SPONSORS

PROJECTS

Nuclear Thermal Hydraulics

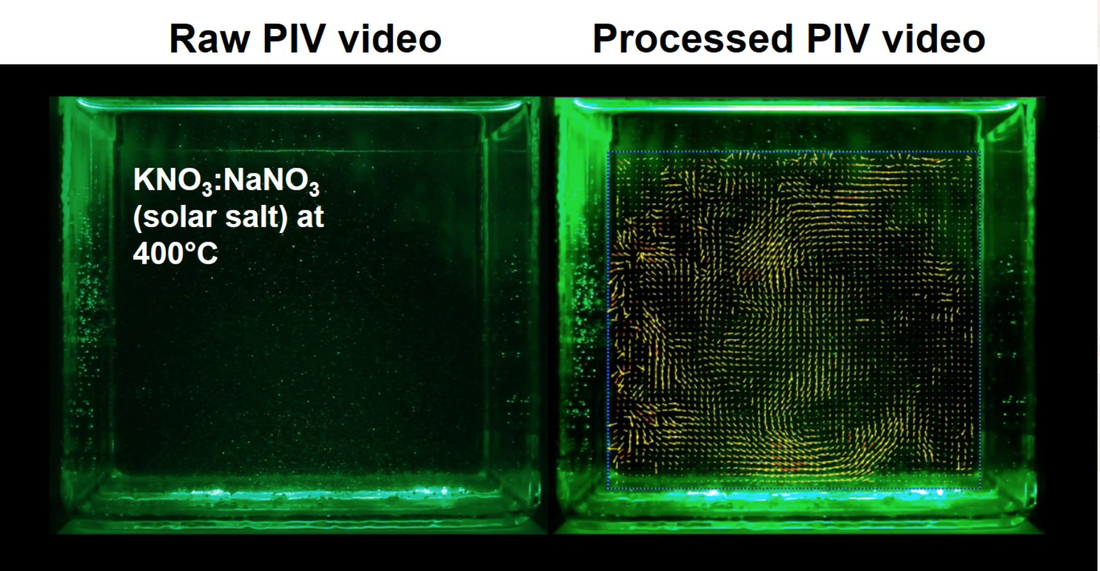

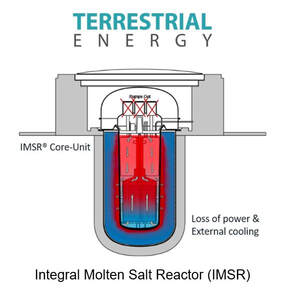

Molten salts have attracted significant interest in the nuclear community for their high operating temperatures and heat capacities, low costs, and favorable neutronics. Optimized molten salt reactor designs will harness the exceptional heat transfer characteristics of molten salts to improve decay heat removal in accident scenarios without the need for auxiliary mixing mechanisms. Passive safety systems based on these heat transfer mechanisms will simultaneously reduce design complexity & cost while improving safety for groundbreaking nuclear reactor technologies.

Our research focuses on understanding the mechanisms governing heat transfer by radiation and natural convection in molten salts, which will facilitate better predictions and improved analytical models for rapid and reliable design calculations. We are applying non-invasive (optics-based) measurement techniques to study phenomena which are inaccessible to traditional invasive (probe-based) measurement techniques. By enabling quantitative thermal hydraulic measurements in molten salts, our work will support the rigorous validation of analytical models used to design and license Generation IV nuclear reactor technologies.

Our research focuses on understanding the mechanisms governing heat transfer by radiation and natural convection in molten salts, which will facilitate better predictions and improved analytical models for rapid and reliable design calculations. We are applying non-invasive (optics-based) measurement techniques to study phenomena which are inaccessible to traditional invasive (probe-based) measurement techniques. By enabling quantitative thermal hydraulic measurements in molten salts, our work will support the rigorous validation of analytical models used to design and license Generation IV nuclear reactor technologies.

Concentrated Solar Power

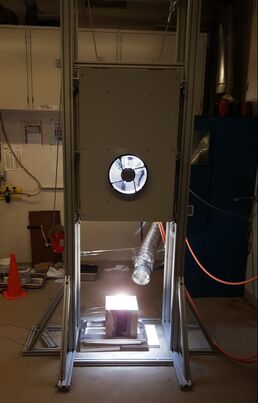

In a concentrated solar power plant, natural sunlight is concentrated hundreds to thousands of times onto a receiver where the sunlight is converted into heat, which in turn can be used for power generation. Traditional solar receivers in tower technology consists of arrays of opaque tubes which absorb the concentrated sunlight, which in turn transfer the heat to a heat transfer fluid flowing inside. Directly irradiated and volumetrically heated semi-transparent solar receivers promise to enhance peak solar flux limits relative to surface absorbers and enable simpler receiver designs with integral thermal energy storage. One leading example of this alternate design is the concept of volumetrically absorbing molten salts, such as the CSPonD concept. However, the direct solar radiation absorption in molten salts presents a complex heat transfer problem consisting of interactions between solar radiation, natural convection, and volumetric heating which makes it hard to predict the system behavior and optimize its design. We are developing theoretical models to identify key parameters influencing the system performance. The theoretical findings are then validated experimentally by replicating volumetric solar thermal receiver conditions at our lab using a 6.5 kW solar simulator. We aim to develop comprehensive design and operation guidelines for an optimal volumetric receiver and collaborate with industrial partners for a commercial scale-up.

Thermal Energy Storage

Thermal Energy Storage Concepts for Process Heat

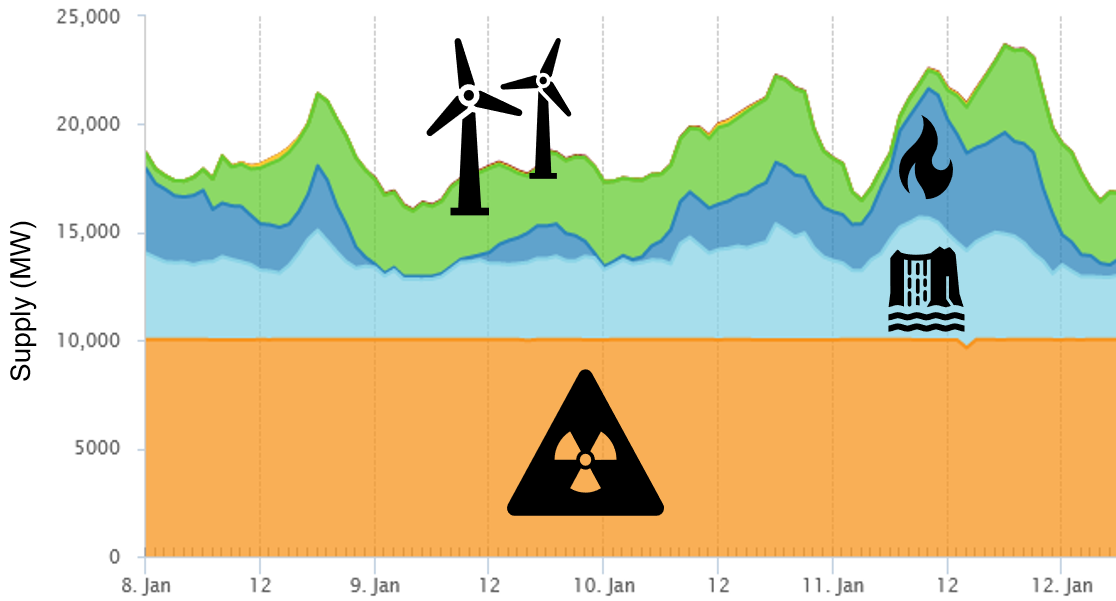

Industrial process heat has been a challenging sector to decarbonize, as there are few clean energy sources with both high availability and low cost compared to fossil natural gas. Intermittent renewables offer the lowest-cost clean energy, but require energy storage in order to reach a high penetration factor.

When the energy end-use is medium-temperature heat, it is possible to use thermal energy storage to storage intermittent renewable energy, which will be more cost-effective than electrical batteries. Low-cost thermal storage will therefore allow industry to use on-site renewables and/or cheap off-peak grid power for 24/7 process heat loads. Storage will be even more critical in the decarbonization of industries with batch processes, in order reduce their peak energy demand. At the same time, lower-cost energy storage will facilitate the overall integration of intermittent sources on the wider grid.

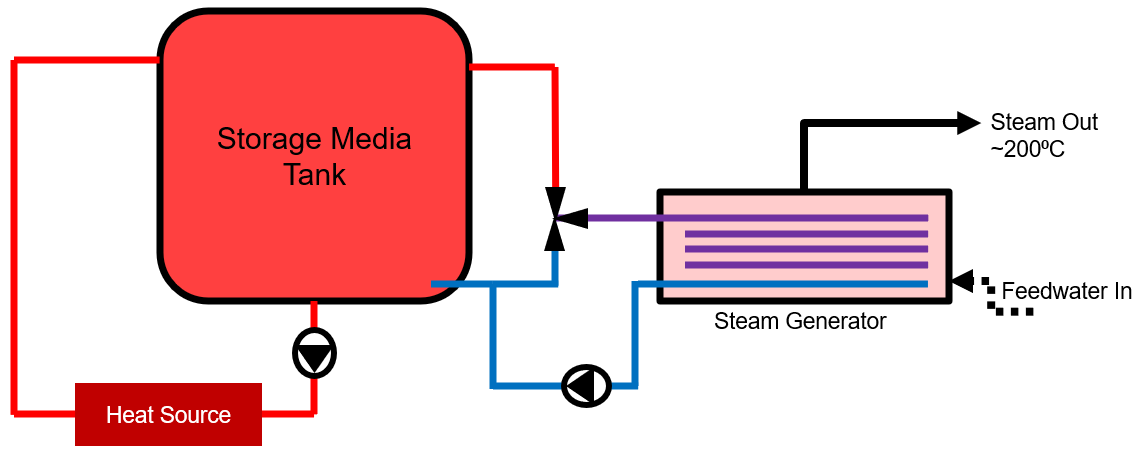

Historically, medium- to high-temperature thermal energy storage (TES) has mainly consisted of molten salt tanks in concentrated solar power plants, to store heat for overnight electricity generation. Adapting this technology to industrial heat applications requires changes in temperatures, charging and discharging methods, and an order-of-magnitude reduction of scale.

We are currently performing a feasibility study of scaled-down molten salt storage for industry, along with preliminary work on both alternative storage media and on alternative heat exchange concepts to improve smaller-scale molten salt storage.

When the energy end-use is medium-temperature heat, it is possible to use thermal energy storage to storage intermittent renewable energy, which will be more cost-effective than electrical batteries. Low-cost thermal storage will therefore allow industry to use on-site renewables and/or cheap off-peak grid power for 24/7 process heat loads. Storage will be even more critical in the decarbonization of industries with batch processes, in order reduce their peak energy demand. At the same time, lower-cost energy storage will facilitate the overall integration of intermittent sources on the wider grid.

Historically, medium- to high-temperature thermal energy storage (TES) has mainly consisted of molten salt tanks in concentrated solar power plants, to store heat for overnight electricity generation. Adapting this technology to industrial heat applications requires changes in temperatures, charging and discharging methods, and an order-of-magnitude reduction of scale.

We are currently performing a feasibility study of scaled-down molten salt storage for industry, along with preliminary work on both alternative storage media and on alternative heat exchange concepts to improve smaller-scale molten salt storage.

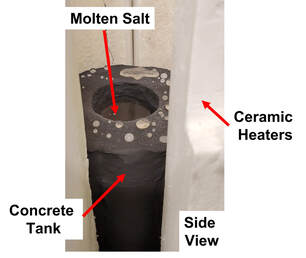

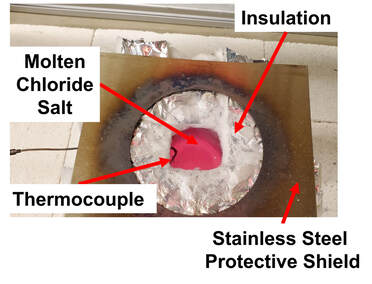

Thermal Energy Storage Materials

Molten salts are widely used as a thermal energy storage media in concentrated solar power plants due to their low cost and high heat capacities. However, molten salts in general, and chloride salts in particular, are highly corrosive towards metals and thus require special stainless steel grades for storage tank construction, which can be up-to 4 times more expensive than a regular grade stainless steel. Therefore, the primary cost driver for high temperature chloride salts is the tank material instead of the salt itself which limits the commissioning of high temperature thermal energy storage plants. We are developing low-cost engineered concrete based molten salts storage tanks which will solve the problem of high capital costs associated with high temperature thermal energy storage systems.

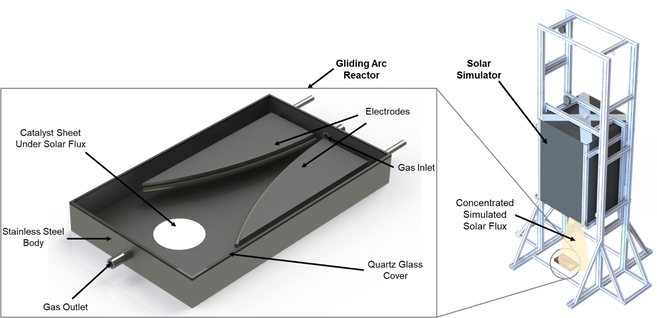

Solar-Plasma Catalysis for Ammonia Synthesis

Ammonia is one of the highest volume chemicals produced globally. Most of the ammonia is used to produce fertilizers utilized in over half of the total food production worldwide. Currently, ammonia is synthesized using the Haber-Bosh process, which requires very high temperatures and pressures, making it highly energy-intensive. Some alternatives to the Haber-Bosh process are currently being studied to help reduce energy consumption. However, none of the processes can currently be commercialized due to their low ammonia yield.

Solar and plasma ammonia synthesis are two of the processes currently being studied. Both processes utilize the same catalyst, usually metals or metal oxide. This means that the processes could potentially be combined to exploit operational synergies. Moreover, concentrated solar power could provide heating for the catalyst, theoretically increasing the yield. This project is focused on exploring the possibility of synthesizing ammonia using a combined Solar-Plasma Catalysis process and paving the way for future work.

Solar and plasma ammonia synthesis are two of the processes currently being studied. Both processes utilize the same catalyst, usually metals or metal oxide. This means that the processes could potentially be combined to exploit operational synergies. Moreover, concentrated solar power could provide heating for the catalyst, theoretically increasing the yield. This project is focused on exploring the possibility of synthesizing ammonia using a combined Solar-Plasma Catalysis process and paving the way for future work.